-

電話客服

400-7007-555 -

微信客服

-

在線客服

-

公眾號

回到頂部

發布時間:2023-07-08

發布時間:2023-07-08

來源:

來源:

瀏(liu)覽量:3046

瀏(liu)覽量:3046

Application Area:Iron & Steel Industry

Process:Coke Making

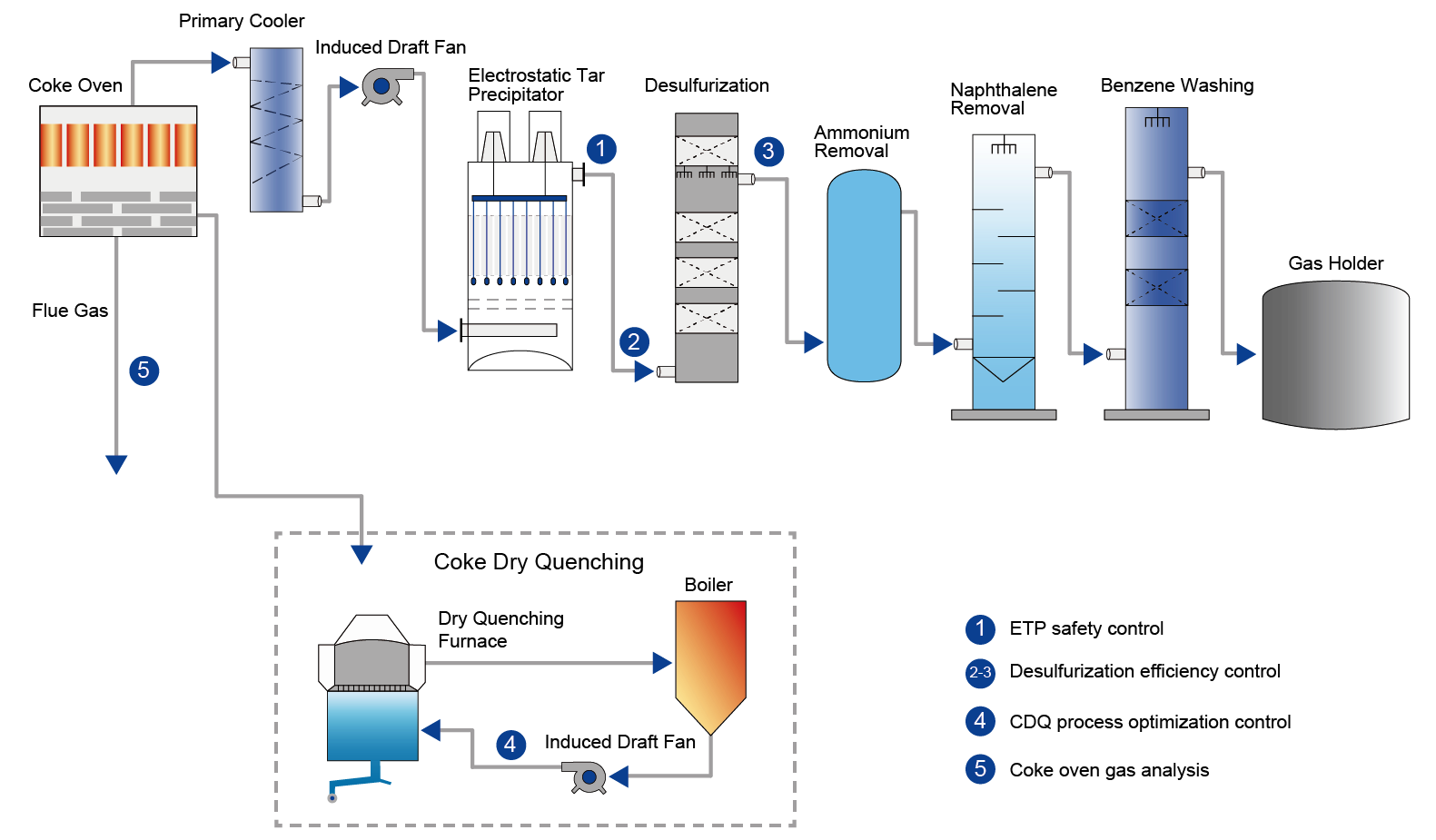

Measuring Components:O2, H2S, CO, CO2

Application Scenario:

Coking coal is converted to coke by driving off impurities to leave almost pure carbon. The physical properties of coking coal cause the coal to soften, liquefy and then resolidify into hard but porous lumps when heated in the absence of air.

The coking process takes place in a coke oven that consists of heating coal to around 1000-1100 °C in the absence of oxygen to remove the volatile compounds. Once pushed out of the vessel the hot coke is then quenched with either water or air to cool it before storage or is transferred directly to the blast furnace for use in iron making. The volatile matter and moisture that are driven off during the coking process are collected, dried and cleaned. The resulting coke oven gas is recovered or transported for downstream use.

FPI Solution:

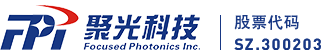

Working Flow of Coke Making Process

Sticky tar and fine coke generated in the production process made the sample collection could be harsh, conventional sample collection method has a low efficiency under such a harsh condition, and it causes massive maintenance as well. FPI adopts pioneering TDLS technology to measure the concentration of process gases, with a non-contact laser and sensor combined with continuous purge results in virtually maintenance free.

LGA-4100 Laser Gas Analyzer

Based on the Tunable Diode Laser (TDLS) technology, LGA-4000 is a highly reliable laser gas analysis system that monitors various toxic and hazardous substances (HF, NH3, H2S, HCl) from stack emission with high accuracy, strong reliability and is virtually maintenance-free.

LGA-4500IC Laser Trace Gas Analyzer

It is the latest achievement of FPI in laser gas analysis, which combines diode laser absorption spectroscopy (TDLS) and integrated cavity output spectroscopy (ICOS) perfectly turn, enhances the measuring sensitivity hundreds of folds. It provides the best solution for trace gas analysis in the natural gas, petrochemical, chemical, and steel industries.

GRD-2000 Thermal Conductivity Gas Analyzer

It is designed to continuously measure the concentration of a single component of interest in a flowing gas mixture. The measurement is based on the different thermal conductivity of the individual components of the sample stream.

If any interests in these products, please feel free to visit FPI's official online store: